Can a Small Block Chevy Be Built for Economy? Part 1

Al Ritter

I have been the owner of a 1965 El Camino for over 10

years, and to be honest it’s become dated. The original hi-compression (11 to

1) over cammed engine has become finicky and almost impossible to tune with

today’s gas, and the iron heads certainly have promoted detonation. The M-20 4

speed trans and the 3:73 rear axle have teamed up with the engine to return a

miserable 11 MPG with a light right foot on the highway and an even more

miserable 8MPG around town. If all my modifications work the way I intend them

to, I expect my fuel mileage to increase to 25MPG.

|

| Engine bay painted and awaiting new engine |

In today’s demands for economy and performance this is

unacceptable. What can be done with a typical small block that most consider a

poor candidate some two engine series ago? There is no doubt that a better

candidate would have been an LT-1 to LT-4 series or better still an LS series

engine complete with fuel injection.

What do you do when all your surplus parts revolve around

the basic 350 engine? Do you discard all those parts and go with an updated

engine assembly, or do you update and refine a tried and true engine combo? My

answer was simple, apply todays technologies to the old tried and true 350, and

I’ll tell you about my path and part selection as we go along.

To begin with today’s cars rely on lighter weight

materials to create a more gas mileage friendly package. Although I could swap

parts of the El Camino for fiberglass or carbon fiber, the return of gas

savings vs cost of purchase doesn’t make that a viable option. The weight of

the El Camino is -------- and although that is no light weight, it rivals most

mid-size cars today. Another problem is aerodynamic drag and the front end of a

1965 El Camino is certainly no 2014 Corvette! Unfortunately there isn’t much we

can do about that other than maybe add a front spoiler, but we will handle that

at a later point in time as we fine tune the combo.

|

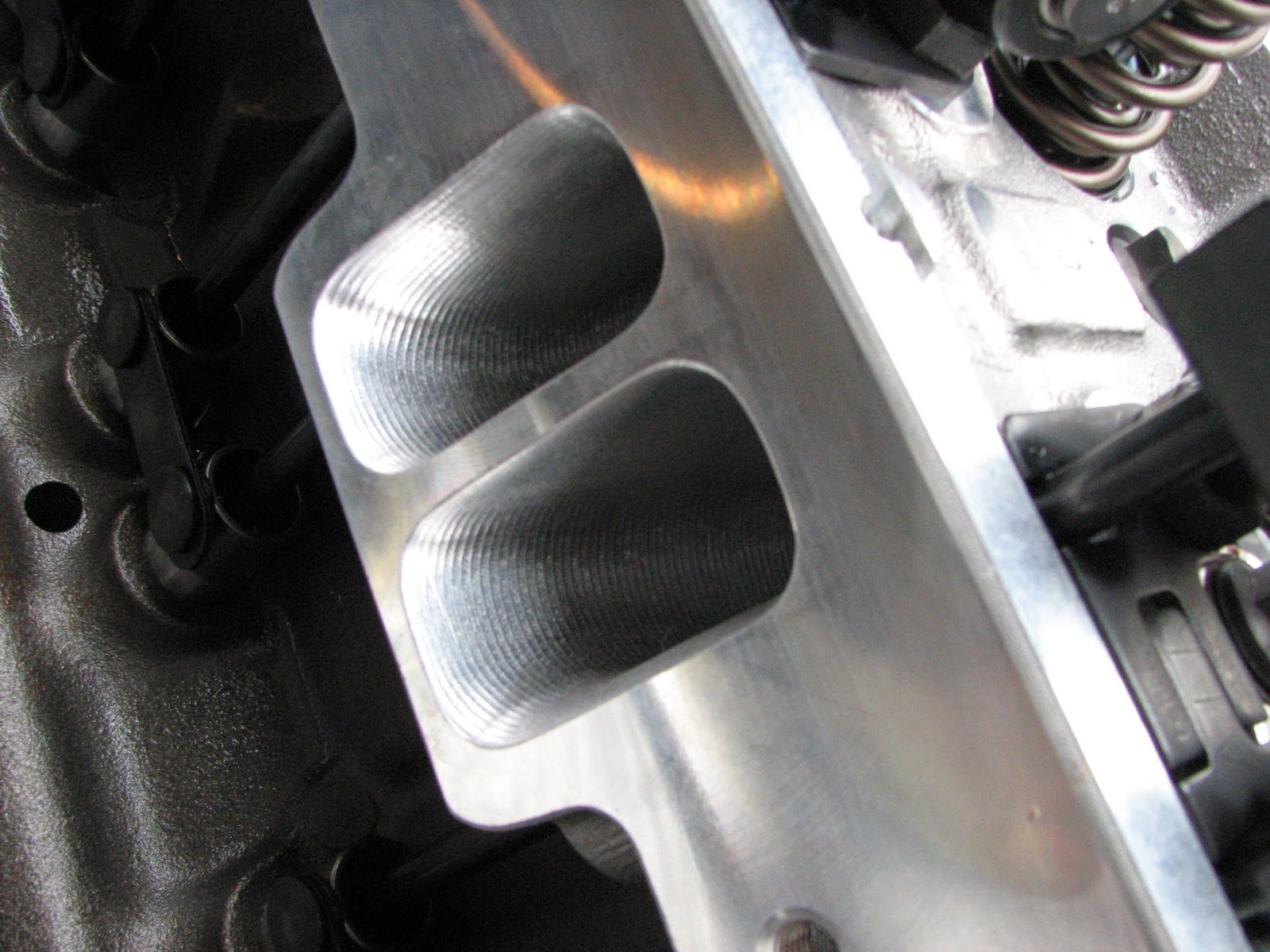

| Full CNC ported |

The engine a 040 over 350 will displace 357 cu in. It has

a factory forged crank and will house Mahle slightly dished pistons (approx. 9

to 1) that will have a low drag coated skirt and thin rings. This will allow me

to run 87 octane fuel another target of mine. I will also be using a 6.0 rod.

AFR heads will promote a swirl port design (65 cc) and will have a small high

velocity runner 180cc part number #916. This head features a straight plug

design to be used with the existing cast iron manifolds that I had extrude

honed years ago and work very well. I will be using a state of the art

hydraulic roller camshaft from Comp Cams. No standard on the shelf design has a

primary intent to give high miles per gallon so a custom grind had to be made,

and these are the specifications, .500 on both the intake and exhaust with the

1.6 rockers, duration is 194 degrees on the intake and 206 on the exhaust, and the

overlap is 110 degrees. The heads will be ordered direct from AFR with lower

weight beehive type LS valve springs set at 125lb. seat pressure. Everything

that is low friction will be utilized including bearings and rings and things

like a Moroso oil pan with a built in windage tray. While initial break in will

be done with a high zinc motor oil, it will be later changed to a full

synthetic.

|

| FAST EZ EFI kit and my manifold (not supplied in kit) |

|

| Filter and Pump |

I will be using a factory dual plane 1969 Z-28 302 intake

with a state of the art FAST EZ EFI fuel injection retrofit system. This system

is an easy to install closed loop throttle body to replace the carburetor. Most

of the electronics and sensors are hidden nicely within the design and are well

hidden. It comes with a hand held programming screen that will have me up and

running with minimal programming effort. Once running the system will be

self-learning to maximize the ability to run with performance and fuel economy

in mind. Once that system has learned the car, final micro tuning can be done to

hit an exact A/F ratio set by the owner, perfect for my aim as an

econo-machine! Although emissions aren’t considered in my state for a vehicle

this old, I’m sure with the addition of catalytic convertors it would fall

within acceptable parameters. Installation isn’t especially hard, just

involved. The fuel system is supplied with the kit, 3/8 fuel injection compliant rubber hose with an assortment of press lock AN fittings. Luckily the car had a sump welded into the tank by a previous owner so the line kit could be easily setup from that point. The pump and filter is a simple affair and was attached to the gas tank crossmember.

|

| pickup and pump |

|

| original fuel line used as return |

A return line had to be used so the old feed line was used after a quick blow with an air gun to remove the nylon screen from the end in the tank.

The wiring harness has rather bulky connectors on both ends and FAST

supplies you with a HUGE grommet for the firewall requiring a 2 1/8” hole to be

drilled! Once the harness has been fed into the grommet you are left with ¾” of

conduit in a 2” hole…..a tad much to “caulk.” I chose rather to buy a smaller

grommet and feed all the connectors through the firewall individually to the

underhood connections so I have less area to caulk.

The wiring harness has rather bulky connectors on both ends and FAST

supplies you with a HUGE grommet for the firewall requiring a 2 1/8” hole to be

drilled! Once the harness has been fed into the grommet you are left with ¾” of

conduit in a 2” hole…..a tad much to “caulk.” I chose rather to buy a smaller

grommet and feed all the connectors through the firewall individually to the

underhood connections so I have less area to caulk.

This certainly challenged my patience, but made for a much cleaner installation in an area that would be seen by the general public. Mounting the handheld controller for the unit proved difficult because of the curved dash for the 65 Chevelle. Although not required for daily operation, constant real time monitoring is a welcome relief to the idiot lights that was original equipment on the Chevelle. The controller has two cables, one for the telemetry and the other for power through a cigarette lighter. I have cut the lighter connection off and hard wired it into the fuse box. The controller will be mounted via Velcro to the bottom of the dash and a/c unit. Initial indications of self-learning were apparent right off the bat as the idle air controller took over and settled the engine speed to the preset idle rpm.

A fitting for the oxygen sensor had to be drilled and welded into the head pipe after following the instructions for distance and angle, this seemed to be the best out of the way place for the installation.

A fitting for the oxygen sensor had to be drilled and welded into the head pipe after following the instructions for distance and angle, this seemed to be the best out of the way place for the installation. After almost 3 hours run time I had noticed that the cold start portion of the program left a lot to be desired, so I called the FAST tech number and explained the problem. He told me that the instructions needed rewriting concerning the adjustment for the throttle body blade adjustment. He wanted me to run the engine until hot and oxygen sensor was active. Then go to the live data section and observe the IAC count. He told me that if I had originally used the instructions to adjust them the count would be in the 30-40 range (which it was.) He told me to use the IAC count to adjust the throttle blades to somewhere in the 15-20 range. That seemed to help the cold start problems immensely.

Other companies had told me that the TKO Tremec

transmission wouldn’t fit into the “A” body GM car without major floor

modifications. American Powertrain informed me that because of their factory

approved transmission case streamlining program the modifications would be

minimal at worst. I installed the transmission and bellhousing onto the engine

to be installed as one unit. Because of additional length of the transmission

this made the combined installation tricky to say the least. Even with my state

of the art tilting engine crane the entire assembly had to be swung sideways to

make it into the body combo. Once the transmission was in the tunnel things

improved. Only one bolt touched inside the tunnel and the additional clearance

was accomplished with a simple bottle jack and a piece of 5/8” round bar stock.

The shifter is pretty cool and offers 16 different possible combinations to

accommodate almost any body style.

The shifter (a short handled Hurst style clone) fit right into my existing factory style hole. The transmission requires a GM equivalent fluid to properly break in the synchronizer set, and 2 quarts were added to be later changed after proper break in procedure with an approved Mobil 1 synthetic. A custom driveshaft and yoke was supplied as part of the kit and after a few simple measurements, one arrived at my door within 3 days! A work of advice when ordering the driveshaft according to the instructions supplied with the kit…..subtract an inch from your final measurement as my driveshaft is a bit too long.

A custom polyurethane trans mount was supplied

with the kit and after finding two non-supplied metric Allen headed fasteners

the install was simple. The crossmember frame mounts had to be redrilled to accommodate

the longer length of the transmission, but no big deal. The supplied clutch

seems to have a bit more chatter than I’d prefer but it has a 200 mile break in

period so I’ll wait until that period has passed before making my final

judgment. The reverse light switch was faulty from the factory and a

replacement had to be ordered. As it turns out the reverse light switch wasn’t

bad. There were two electrical connections on the transmission, one on the end

of the transmission tailshaft that had a harness attached and one farther up in

the middle of the driver’s side that had no harness. The instructions never

really said which one was the reverse light switch, and I had assumed that the

one on the tailshaft was the reverse light switch, well you know what they say

about the word “assume.” I now know it was the one in the middle of the trans

on the driver’s side……..you have been warned!

The shifter (a short handled Hurst style clone) fit right into my existing factory style hole. The transmission requires a GM equivalent fluid to properly break in the synchronizer set, and 2 quarts were added to be later changed after proper break in procedure with an approved Mobil 1 synthetic. A custom driveshaft and yoke was supplied as part of the kit and after a few simple measurements, one arrived at my door within 3 days! A work of advice when ordering the driveshaft according to the instructions supplied with the kit…..subtract an inch from your final measurement as my driveshaft is a bit too long.

|

| Poly Transmission mount |

Michelin Pilot Super Sport tires will replace the

original setup originally purchased 14 years ago. Michelins were picked for

their longevity, rolling resistance and traction ratings on both dry and wet

surfaces. 225 45R x 18 for the front and 245 45R x 18’s for the rear.

You Tube video:

https://www.youtube.com/watch?v=6Q_VVfCzEUY&list=UUCKaLG_zwxF6kLp9AiUgbcw

You Tube video:

https://www.youtube.com/watch?v=6Q_VVfCzEUY&list=UUCKaLG_zwxF6kLp9AiUgbcw